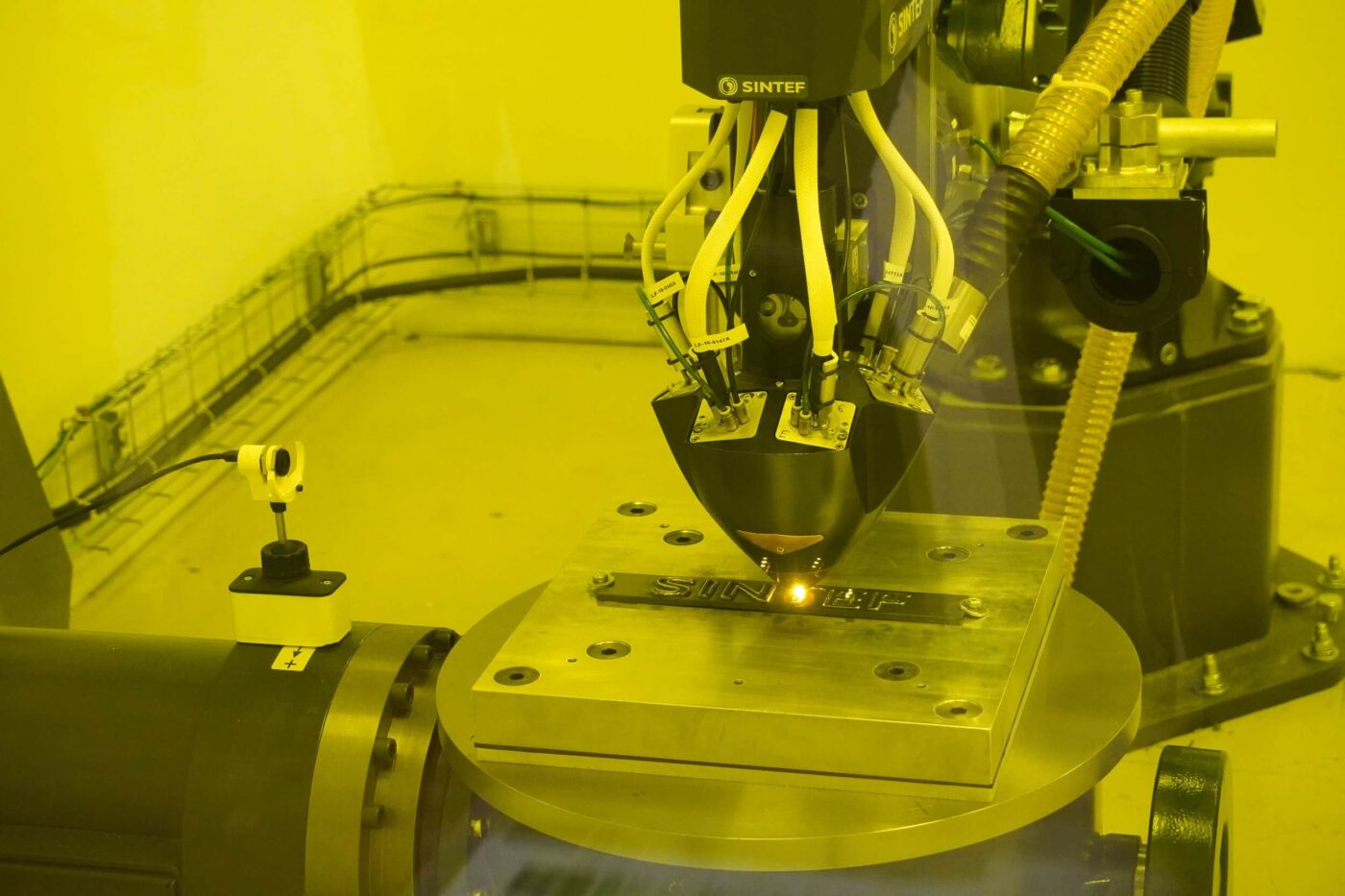

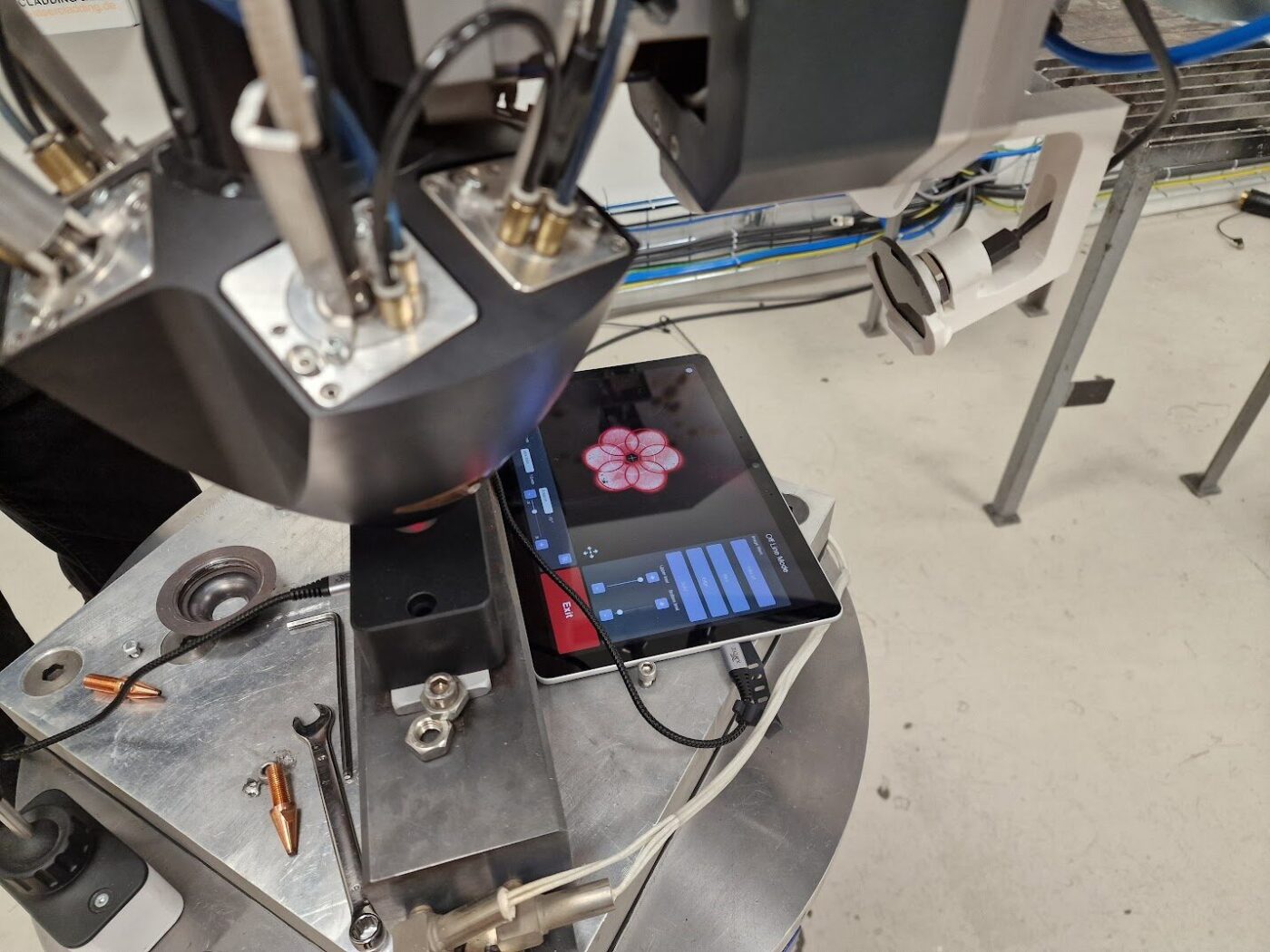

The team has developed models for process optimization, tested for multi-beam control,

laser beam shaping, and high-speed scanning – All key parts of the spearheading technologies that is ALABAMA.

Benefits of the project

Improved quality

This technology significantly improves product quality, backed by advanced verification methods that ensure reliability and precision.

Flexible production

Flexibility is essential for profitability, driving enhanced productivity and optimized performance.

Time-efficient

The shaping strategies will help reduce the time by 90% compared to conventional methods.

Resource-saving

Material usage is optimized to reduce waste and maximize efficiency, ensuring sustainability and cost-effectiveness.

Lower cost

Reducing production costs drives profitability and opens doors to market expansion.

Reduced consumption

The technology aims to reduce the energy consumption as well as green house gasses.

Consortium

The ALABAMA project unites top European research institutions, universities, technology organizations, and businesses, combining expertise to advance metal 3D printing and drive innovation across industries.